Before the cover is painted and mounted in the fuselage, I needed to decide where and what to do with the radio speaker.

The radio I plan to buy has a radio speaker box, but the size could have created an access problem near the batteries and with push rod articulation.

Robert suggested a speaker for the radio and it looks like it would fit in the hatch.

With a little modification to the outside of the speaker-box, I was able to create mounting point on the case face.

I created a pattern of the grill cover and the screw holes.

I was able to cut the openings cleanly with a Dremel tool and drill.

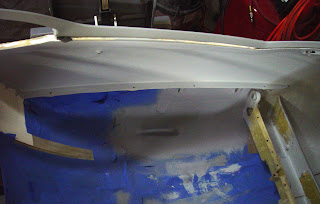

I then did a test fit with speaker housing.

After a final light sanding on the surface, I applied a primer coat, ready for the next steps, Mounting the piano hinge and painting.

What fun, what joy......